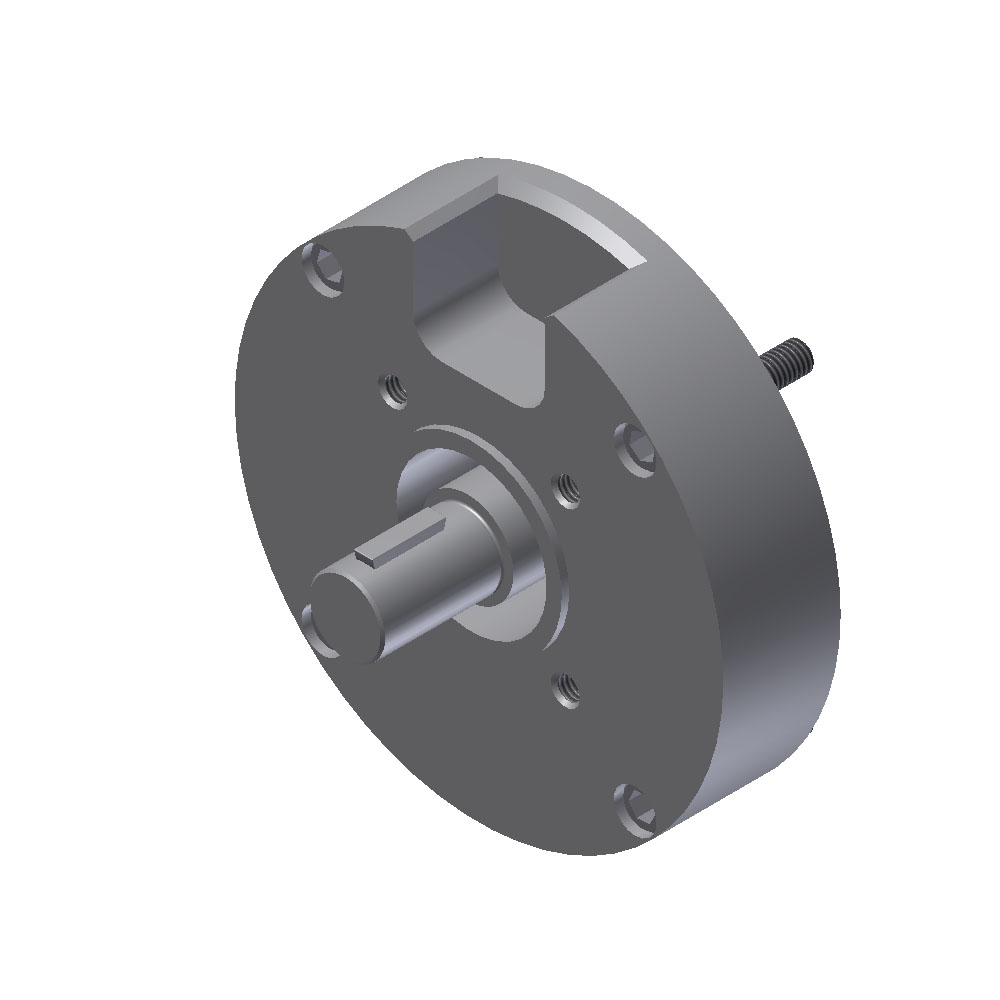

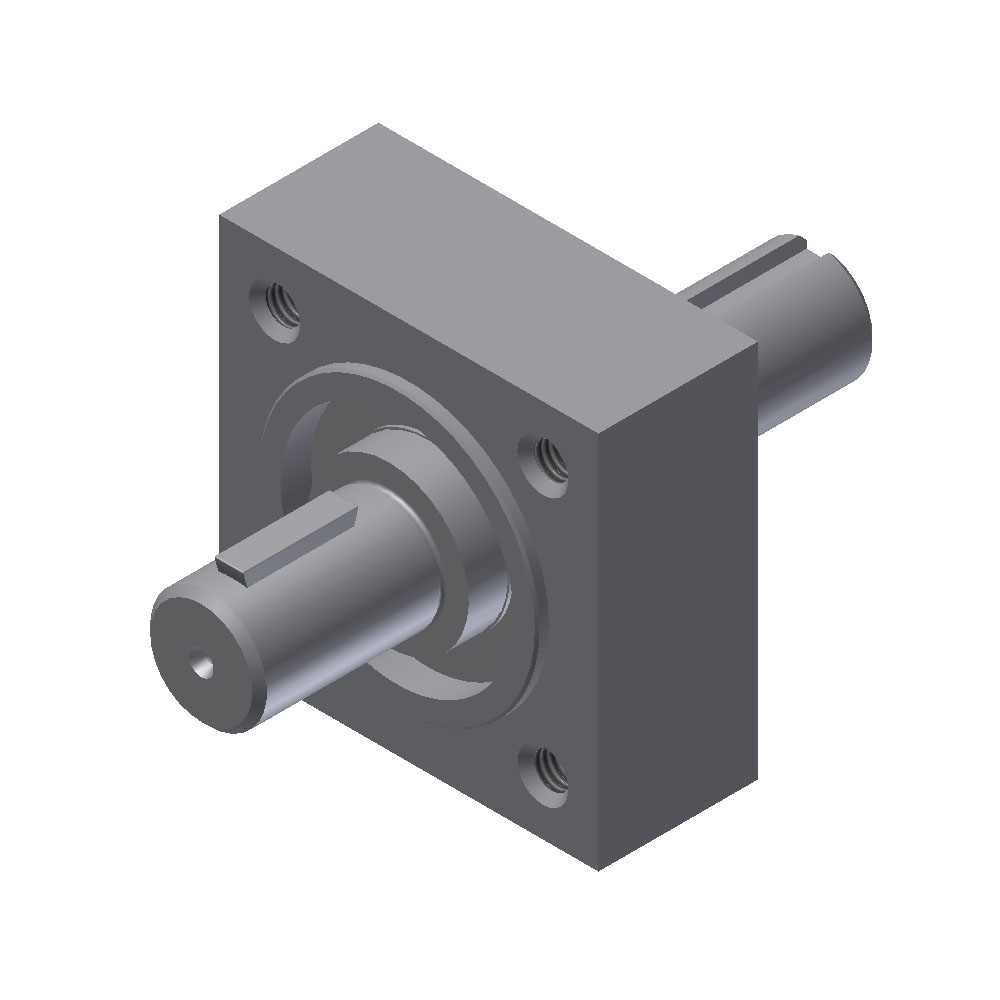

Available Drive Styles for Jiffy-Tap

The Jiffy-Tap can be ordered with choice of 20 hydraulic motor models covering a wide range of speed/torque ratios. Motor selection depends on the tap size, thread pitch, speed, and the hardness of the material to be tapped. Hydraulic motors can be attached in any 90º increment for easy plumbing. All Jiffy motors are reversible.

There is a choice of 8 motor models for medium speed tapping up to 2200 RPM. A choice of another 12 motor models for low speed, high torque tapping with larger taps or when working with harder materials. Consult factory for additional high speed, low torque motors for applications up to 3000 RPM.

Motors A-l through A-4 and M-0 through M-3 are for high speed tapping up to 2200 RPM. Motors B-0 through B-8 are low speed, high torque models for larger taps or harder materials.